Geomembranes are geosynthetic materials made of polyethylene (97.5%), carbon (2.5%) and UV stabilizers. They are used exclusively in systems where it is necessary to ensure watertightness. They are made in several colors, usually black, green and white. The main characteristics are high resistance to tearing and penetration, excellent chemical resistance to organic and inorganic substances and solvents, they are easy to combine, the lifespan of the geomembrane is min. 10 years, are available in different roll thicknesses and widths.

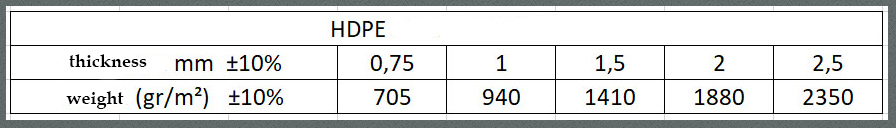

HDPE GEOMEMBRANE, is an insulating material with a very wide range of applications in road and railway structures, municipal investments (eg for sealing waste disposal facilities). HDPE GEOMEMBRANES that are permanently installed in the ground have different functions that arise from the design assumptions, e.g. improving the physical and mechanical properties of construction soil, strengthening the stability of slopes, changing the value and direction of groundwater filtration, creating solid waterproof and impermeable barriers in the soil. All geosynthetic polymer barriers are available in a smooth and textured version. The documents that accompany the geomembrane are certificates and certificates of quality of goods in all respects according to the valid European standards for this material.

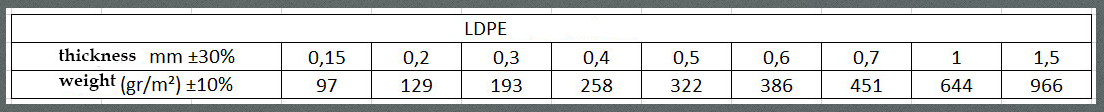

Our highest quality product - LDPE geosynthetic polymer barrier is known for its perfect flexibility, high resistance to index puncture and cracking from corrosion under load. The product does not contain fillers or plasticizers that can migrate during the period of use (unlike PVC geomembranes) and are neutral for the aquatic environment. LDPE geomembrane is recommended especially for applications that require more flexibility, e.g. reduced access to slopes, artificial reservoirs and canals for municipal waste remediation. All geosynthetic polymer barriers are available in a smooth and textured version.

EPDM GEOMEMBRANE is a geomembrane whose elasticity is increased by a rubber waterproofing material produced from ethylene-propene-diene monomers. EPDM geomembrane can be used on all projects where waterproofing is required.

EPDM GEOMEMBRANE CHARACTERISTICS

• Can be applied independently in one layer

• Application can be done by hot wedge welding and hot air fan

• Resistant to UV radiation

• Resistant to plant root penetration

• Non-corrosive material - resistant to aging

• High performance in terms of elongation and elasticity

• Highly resistant to chemical materials

• Not harmful to the environment - can be recycled

• Long service life

• High temperature resistant (-40 C˚, + 120 C˚)

APPLICATION

• Vertical surfaces: terraces and roofs

• Landscape surfaces

• Artificial ponds, fire pools and other pools

• Water tanks and irrigation canals

• Building a foundation

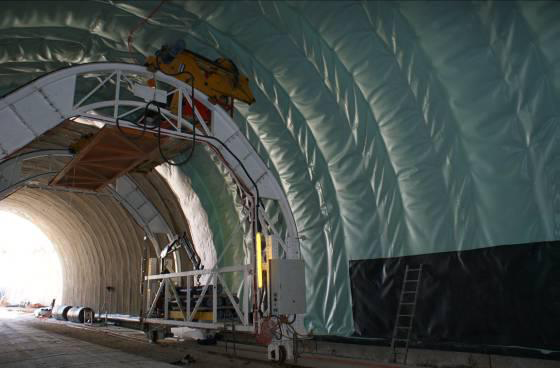

• Tunnels, basements, dams

• Waste disposal sites

EPDM geomembranes are produced in the thickness range 1, 1.2, 1.5, 2.0, 2.5, 3mm. The material is used in foundation, construction of terraces, canals, reservoirs, swimming pools. They are produced on request in a width of 2.05 m while the length is determined according to the needs of the end user.

EPDM KL geomembrane is a specially produced material laminated on one side. The field of application is when used with geotextiles, which saves time for cutting geotextiles. It is used wherever it is necessary to use a membrane without gloss.

It is produced by laminating the desired weight in grams. UV is resistant. The width of the roll is 2.05 m, while the length is determined by the user's request.

PVC GEOMEMBRANE is a two-color geomembrane used as a waterproofing layer for construction and building structures, such as:

• Tunnels and underground galleries

• Underground works

• Covering collapsed buildings

• Underground car parks

Waterproofing PVC GEOMEMBRANE contains a layer of a thin layer of paint on the visible face of the membrane that allows quick visual inspection of any damage to the geomembrane during application. This layer is called "signal-on-layer". PVC GEOMEMBRANE can be used as a single-layer waterproofing system, separate or not, and in the "Stop Vacuum" system. The strips are welded to each other by applying hot air or using a hot wedge, with a manual or automatic welder. Welding can be done with single or double weld. Double lime creates a channel and allows a pneumatic test with air to be performed. PVC GEOMEMBRANE is a reinforced, synthetic PVC-P membrane, produced by coextrusion. It is highly resistant to the influence of microorganisms and root penetration. There is a different color on each side:

• The upper surface (light green), which makes up less than 20% of the total thickness, forms a “signal layer”

• The underside (dark gray) is very resistant to root decomposition and puncture.

PVC GEOMEMBRANE is not resistant to UV radiation. Also available is PVC / 300, which has a non-woven geotextile of 300gr / m2 attached to the underside of the membrane. Civilian use attaches the greatest importance to product quality. That is why PVC GEOMEMBRANE has a quality assurance system according to the ISO 9001 BSI standard MAIN BENEFITS

• Excellent weld

• Contains signal layer

• High resistance to microorganisms and root penetration

• Can be used in a vacuum system

INSTALLATION EQUIPMENT

• Manual hot air welding

• Automatic hot air welding machine

• Automatic double welding machine